Our history

At a time when processing and packaging vegetables was still hard work, Gerd Gillenkirch realised: “There has to be an easier and better way, there have to be effective solutions.” Today, the machines may have changed, but the commitment and passion have remained!

Gerd Gillenkirch, the founder of the company, is born in October 1948. His grandparents and parents are entrepreneurs and they run a potato distributor and a fruit and vegetable shop. Gerd learns early on what hard work means and pitches in after school. He grows up in the post-war period, marked by economic reform and upswing. A time when things could only go up. Commitment, creativity and good solutions are needed for reconstruction.

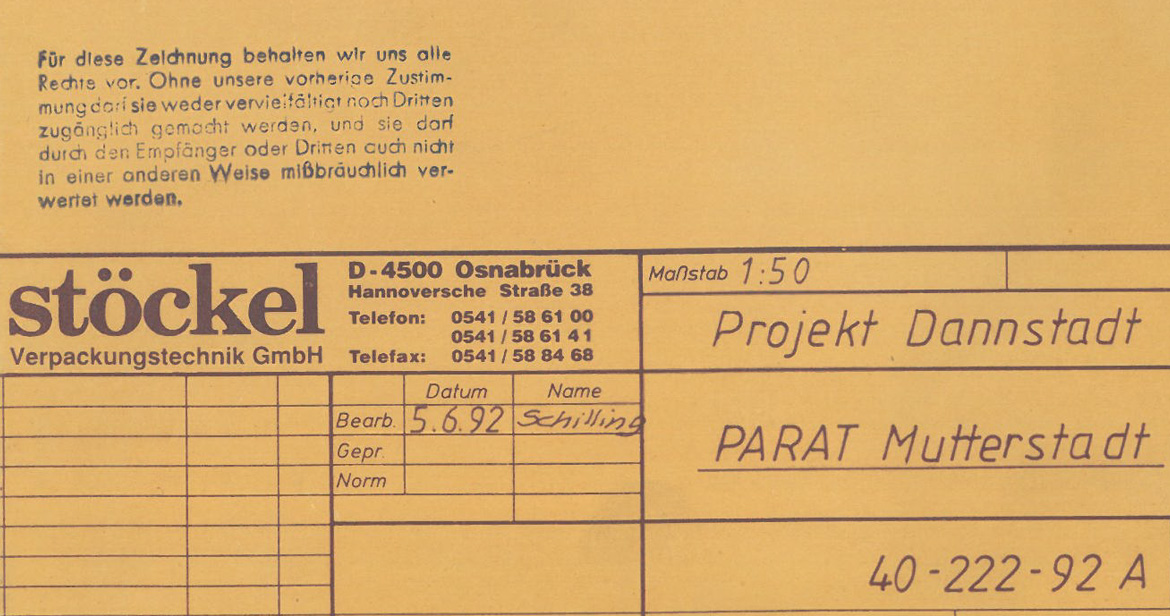

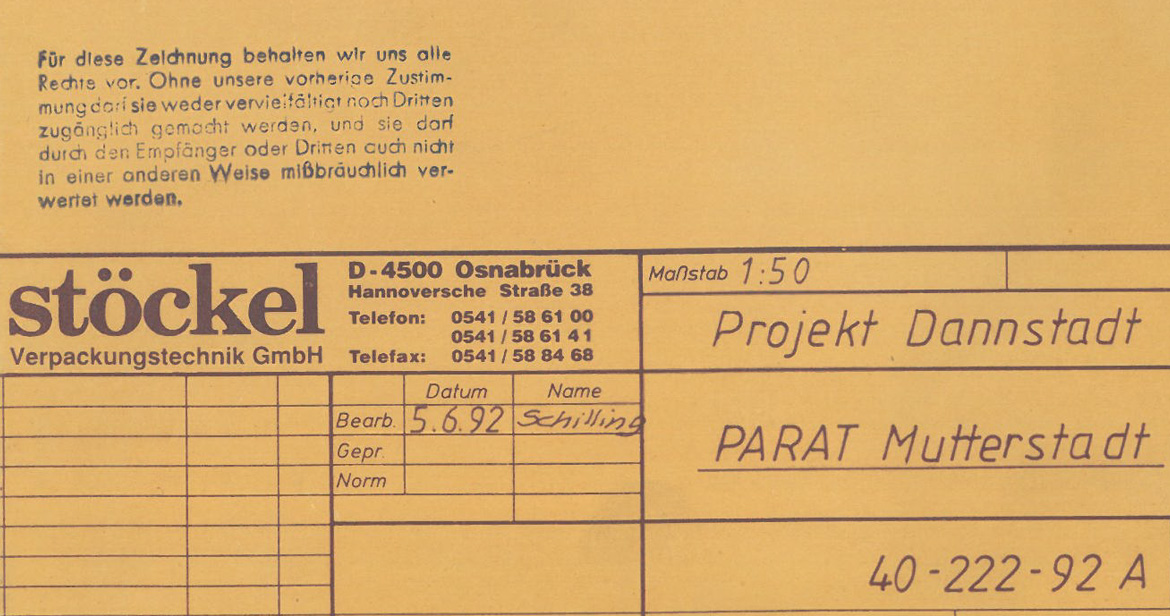

After completing his military service in 1969, Gerd buys a trade licence and starts his own business as a customer service fitter for the Stöckel company. At the same time, he meets his future wife Brigitte, who takes over his bookkeeping.

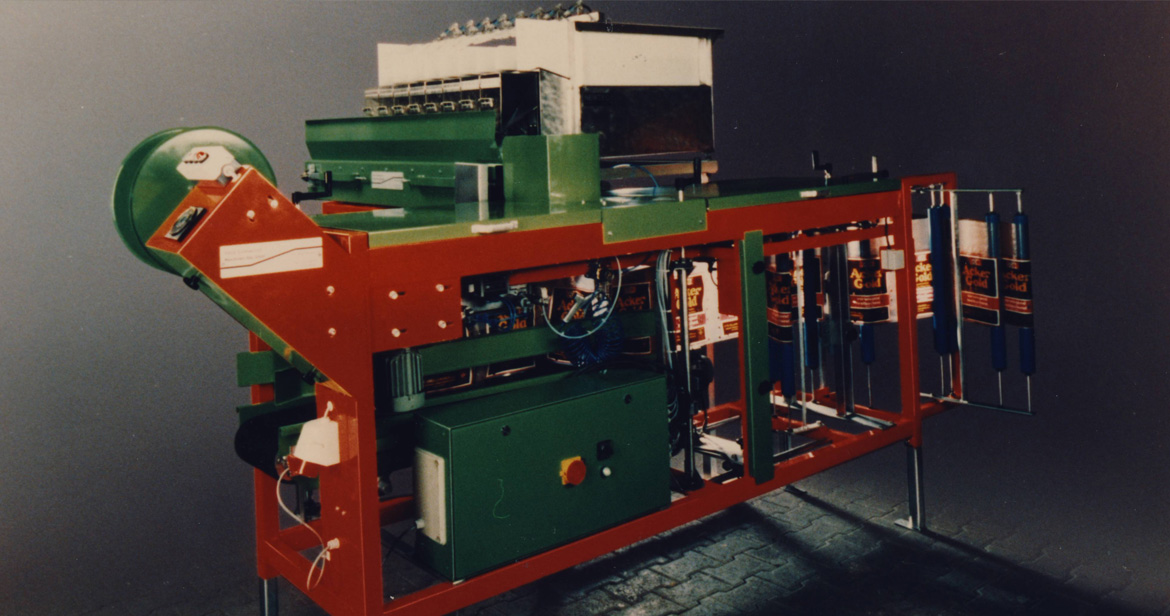

In 1976/ 1977, two patents followed for a “bag packing machine” and an “automatic weighing machine” and formed the foundation for today’s business. Gerd then sells the patent to the company “Lookwood” in Holland. The “Lookwood” company then builds many weighing machines and Gerd Gillenkirch takes over the maintenance of the machines.

At the end of the 1980s, Gerd Gillenkirch got to know the Danish company “Newtec” at a trade fair and the foundation stone was laid for the integration of high-quality weighing machines into the plant concepts.

In 1995 and 1996, the company receives the largest orders in its history. The construction of two weighing and packaging plants including a bunker system at Kartoffel Braun and a company in eastern Germany. The projects become an important basis for the subsequent plant concepts. At the same time, the packaging machines are further developed and the first professional brochures and a small website are created.

In the early 2000s, the company takes over an insolvent conveyor belt manufacturer and builds a new factory building for the production of machines and conveyor belts in Bremervörde.

In 2008, the company receives the order for another important reference project. The company Moespom in Belgium commissions Gillenkirch to build a small and high-quality polishing, sorting and packaging plant. In order to be able to receive international customers, the company simultaneously builds a new administration building and has enough space for new ideas and good solutions.

In 2010, the company receives the order from “AK-Agarkontor” for the construction of a high-quality washing and sorting plant for table potatoes. Both parts of the plant are first-classly processed down to the smallest detail and are connected with each other in a high-performance manner and represent a further milestone in quality and hygiene.

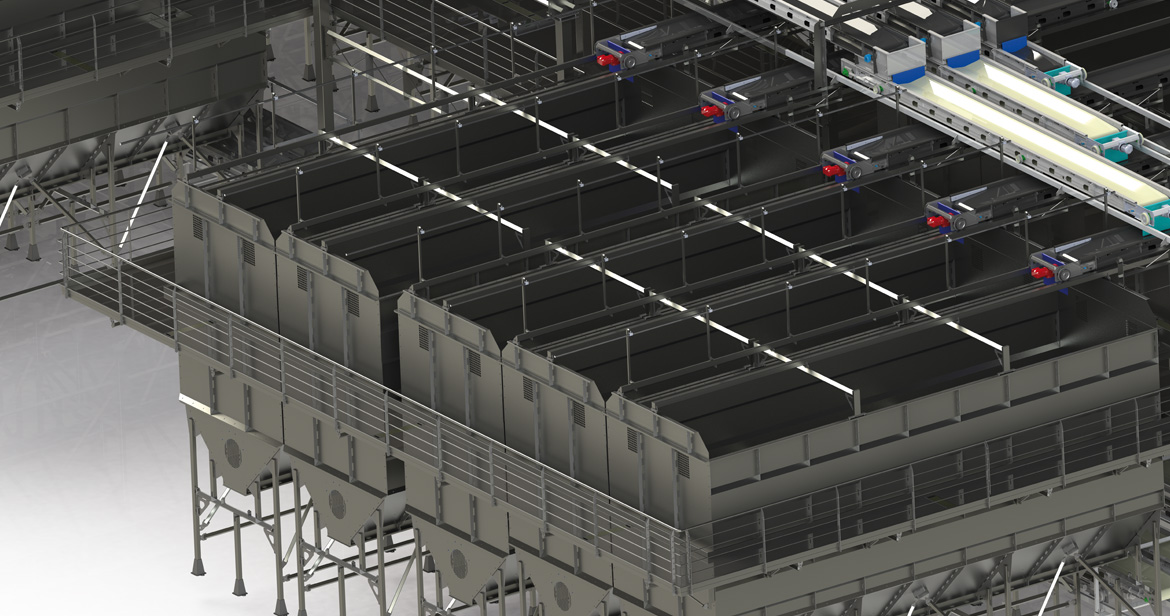

The company receives the largest order in its history: the construction of a washing and hopper plant for a leading French fries manufacturer in the USA. The plant will be manufactured in 2012 at the three locations Dinslaken, Bremervörde and Jihlava. In January 2013, the plant goes into operation in the USA with a total capacity of more than 30,000 truckloads of potatoes per year. The successful realisation sets new standards in conception, processing, quality, hygiene and performance requirements.

1948

1966

1969

1973

1976 / 1977

1980

1988

1993

1995 / 1996

1997

2000

2001 / 2003

2008

2009 / 2010

2010

2012

2012 / 2013

2014 / 2015

In 1966, school is over and the serious side of life begins. In a conversation with his father, Gerd discusses what he should learn in the future. According to his father, the future is electric. After training as a high-voltage electrician at AEG in Mülheim a. d. Ruhr, he completes his military service.

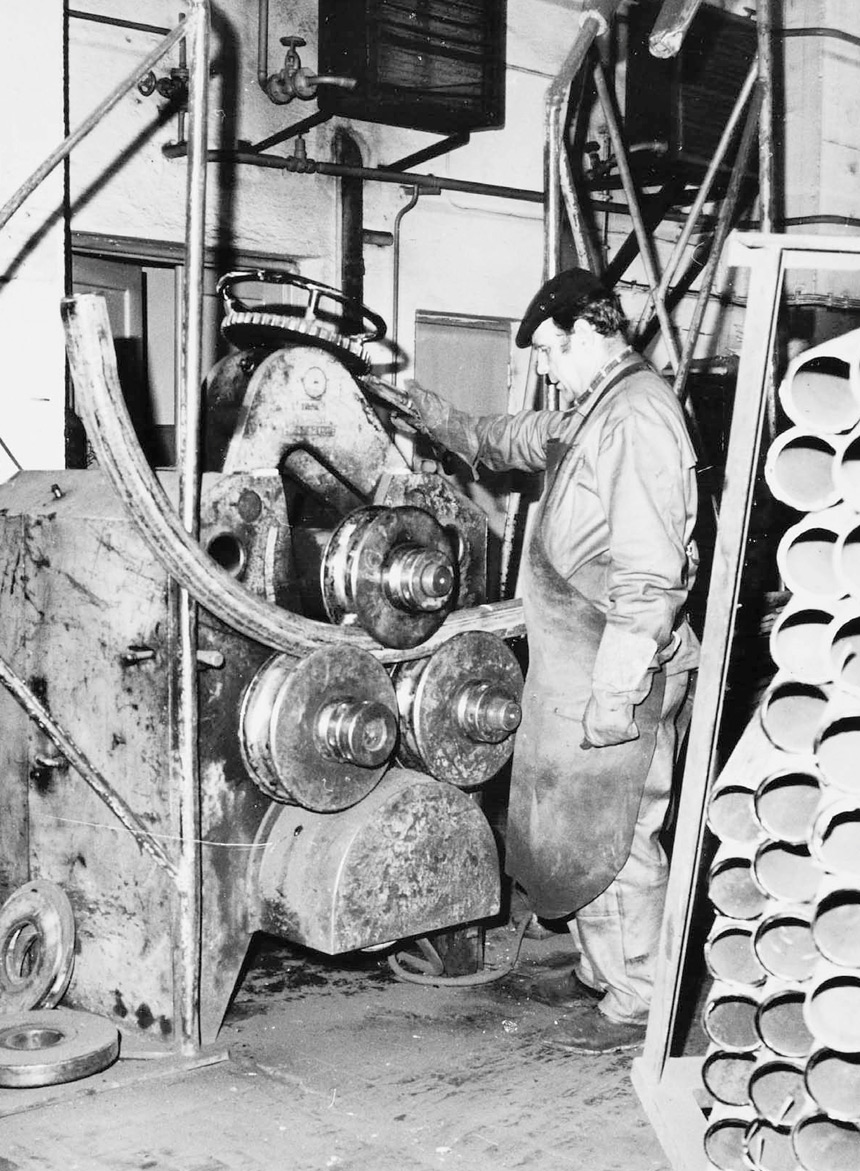

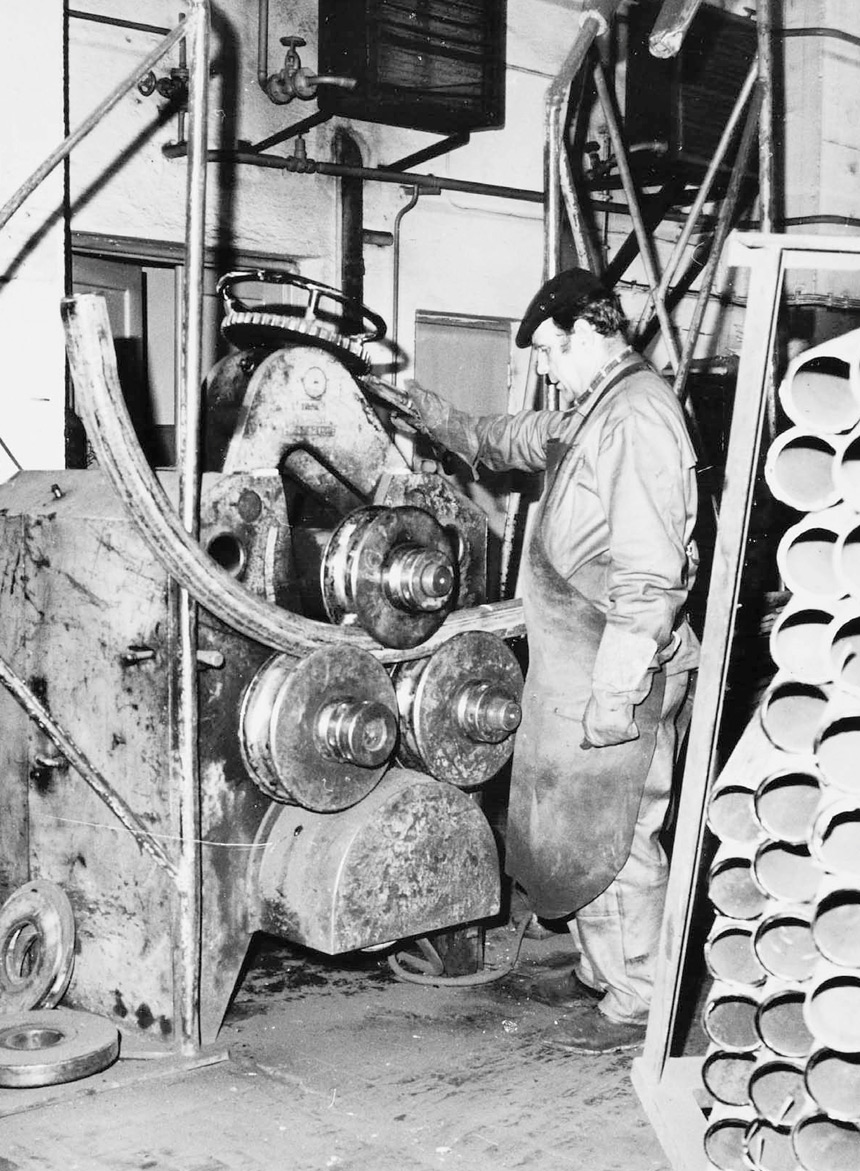

In 1973 Gerd builds his first own workshop, in the garage of his father’s potato farm. He starts repairing machines and building small conveyor belts on his own.

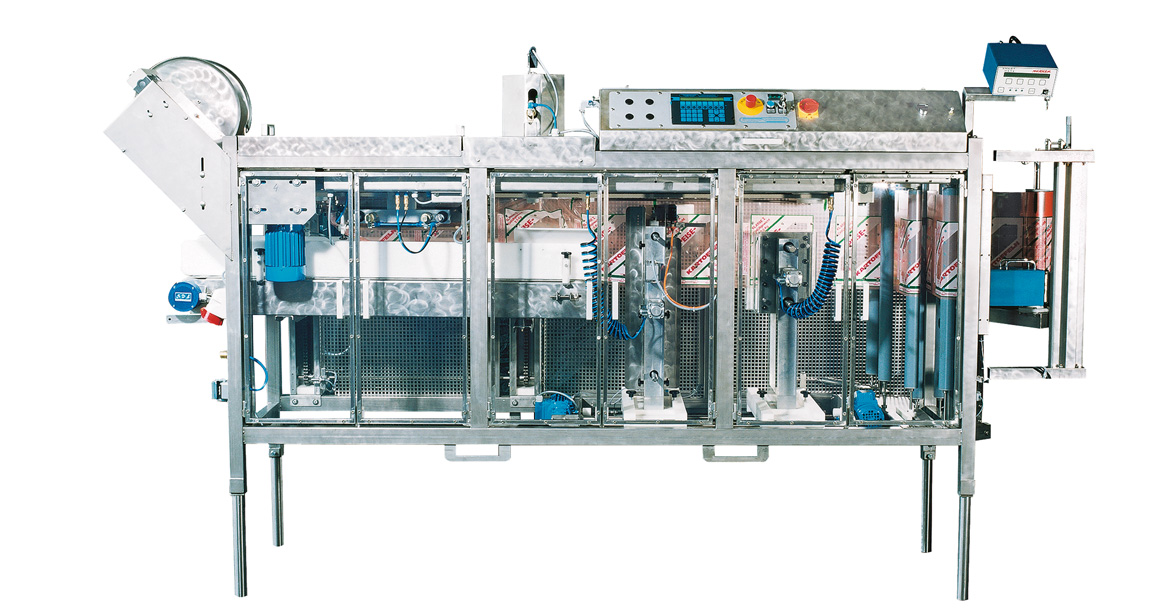

In 1980, Gerd Gillenkirch decides to expand the business. He builds the first potato bunker system with cooling for the Thissen company in Straelen. Due to the high demand from many customers for bunker and conveyor systems, Gerd Gillenkirch builds his first factory building in Dinslaken and hires the first employees. At the same time, the horizontal film sealing machines are manufactured and realised in small plant concepts.

With the fall of the Berlin Wall, the nineties got off to a good start. Michael Gillenkirch, Gerd’s son, started in the company in 1993 and new opportunities for plant construction in the west and east of Germany opened up.

In the mid-nineties, another key decision is made for today’s machine and plant quality. Production is reorganised, the machines are now made of stainless steel and additional employees are hired.

The company realises its first plant project for the packaging of carrots for “Rocky Lamattina” in Australia in 2001. In 2003, his brother “Russel Lamattina” places an order for a packaging plant for potatoes. The entire plant is built from stainless steel and the first-class workmanship sets a new quality standard in the entire industry. More plants follow worldwide.

In 2009 / 2010 Gillenkirch presents itself to the outside world as a whole for the first time. A corporate image is built up, a general catalogue is created, a new website and our first corporate film lands in the can. At the same time, the design department refines the details of the machines in terms of quality and hygiene and supplements the creation of drawings with the introduction of 3D visualisation.

The company expands its operations in Bremervörde. In May 2012, the company breaks ground for the construction of the new warehouse and loading hall and in September, the company has a total area of 3000 m² for the production of machines and conveyor belts. In order to meet the increasing demands for plant construction, the company founds Fresh Link & Packaging Solutions, based in the Czech Republic, together with Rostislav Bucek.

In 2014/2015, Gillenkirch is implementing a complete plant concept for the processing of table potatoes in Canada. This is the first time that such a complex plant concept is being realised in one assembly step, as in the past similar projects were developed over several years. At the same time, Michael Gillenkirch, the Managing Director of Engineering and Sales, succeeds his father and takes over responsibility for Gillenkirch Packaging Systems as Managing Director.

1948

Gerd Gillenkirch, the founder of the company, is born in October 1948. His grandparents and parents are entrepreneurs and they run a potato distributor and a fruit and vegetable shop. Gerd learns early on what hard work means and pitches in after school. He grows up in the post-war period, marked by economic reform and upswing. A time when things could only go up. Commitment, creativity and good solutions are needed for reconstruction.

1966

In 1966, school is over and the serious side of life begins. In a conversation with his father, Gerd discusses what he should learn in the future. According to his father, the future is electric. After training as a high-voltage electrician at AEG in Mülheim a. d. Ruhr, he completes his military service.

1969

After completing his military service in 1969, Gerd buys a trade licence and starts his own business as a customer service fitter for the Stöckel company. At the same time, he meets his future wife Brigitte, who takes over his bookkeeping.

1973

In 1973 Gerd builds his first own workshop, in the garage of his father’s potato farm. He starts repairing machines and building small conveyor belts on his own.

1976 / 1977

In 1976/ 1977, two patents followed for a “bag packing machine” and an “automatic weighing machine” and formed the foundation for today’s business. Gerd then sells the patent to the company “Lookwood” in Holland. The “Lookwood” company then builds many weighing machines and Gerd Gillenkirch takes over the maintenance of the machines.

1980

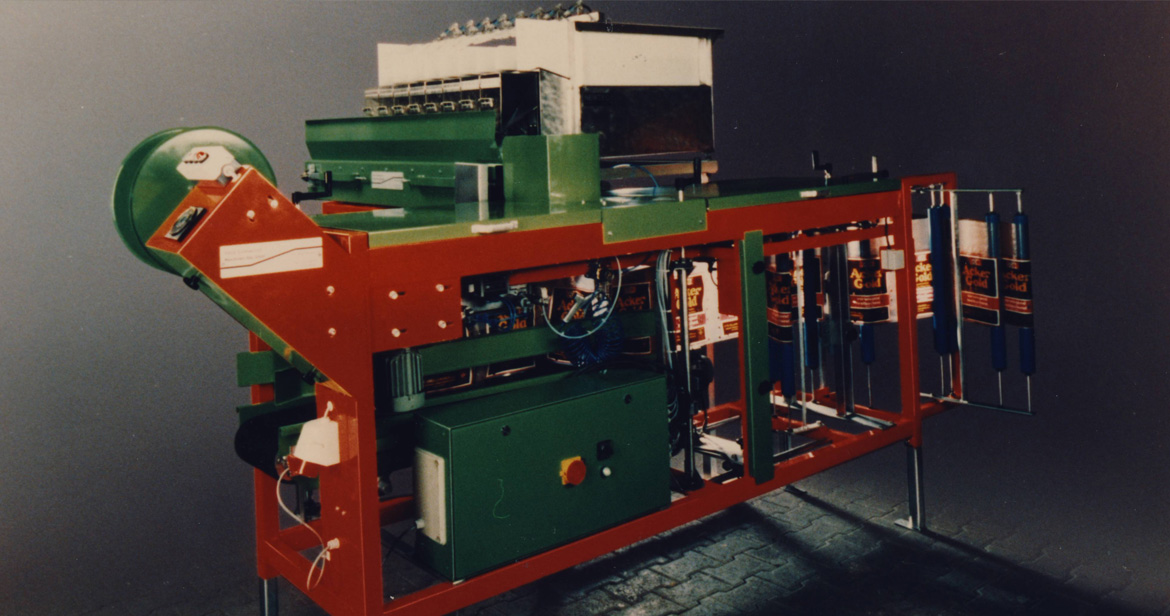

In 1980, Gerd Gillenkirch decides to expand the business. He builds the first potato bunker system with cooling for the Thissen company in Straelen. Due to the high demand from many customers for bunker and conveyor systems, Gerd Gillenkirch builds his first factory building in Dinslaken and hires the first employees. At the same time, the horizontal film sealing machines are manufactured and realised in small plant concepts.

1988

At the end of the 1980s, Gerd Gillenkirch got to know the Danish company “Newtec” at a trade fair and the foundation stone was laid for the integration of high-quality weighing machines into the plant concepts.

1993

With the fall of the Berlin Wall, the nineties got off to a good start. Michael Gillenkirch, Gerd’s son, started in the company in 1993 and new opportunities for plant construction in the west and east of Germany opened up.

1995 / 1996

In 1995 and 1996, the company receives the largest orders in its history. The construction of two weighing and packaging plants including a bunker system at Kartoffel Braun and a company in eastern Germany. The projects become an important basis for the subsequent plant concepts. At the same time, the packaging machines are further developed and the first professional brochures and a small website are created.

1997

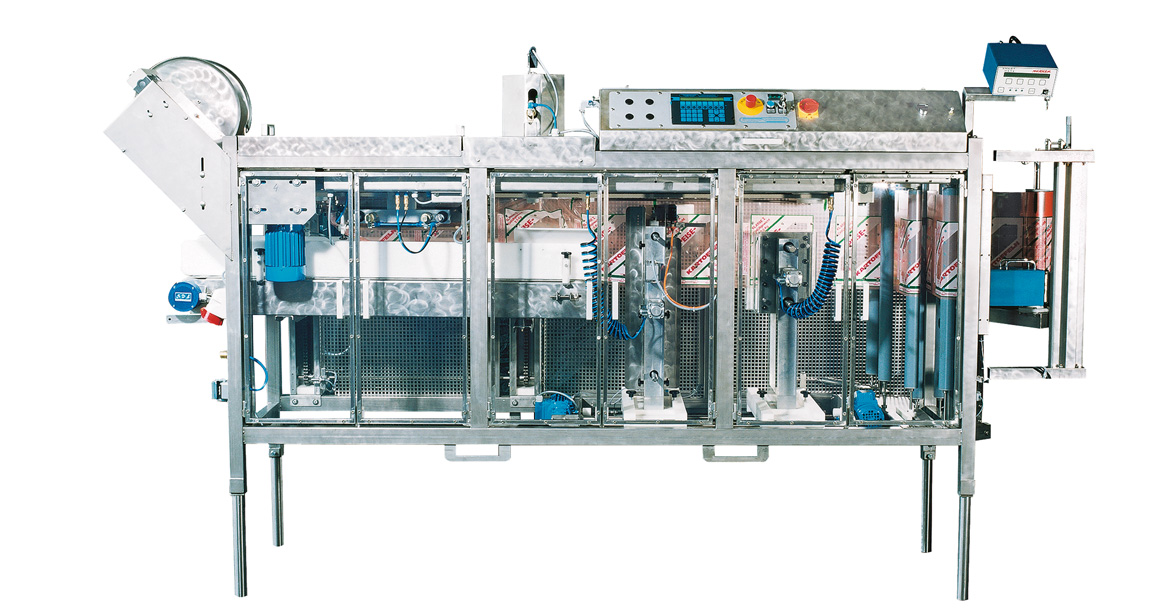

In the mid-nineties, another key decision is made for today’s machine and plant quality. Production is reorganised, the machines are now made of stainless steel and additional employees are hired.

2000

In the early 2000s, the company takes over an insolvent conveyor belt manufacturer and builds a new factory building for the production of machines and conveyor belts in Bremervörde.

2001 / 2003

The company realises its first plant project for the packaging of carrots for “Rocky Lamattina” in Australia in 2001. In 2003, his brother “Russel Lamattina” places an order for a packaging plant for potatoes. The entire plant is built from stainless steel and the first-class workmanship sets a new quality standard in the entire industry. More plants follow worldwide.

2008

In 2008, the company receives the order for another important reference project. The company Moespom in Belgium commissions Gillenkirch to build a small and high-quality polishing, sorting and packaging plant. In order to be able to receive international customers, the company simultaneously builds a new administration building and has enough space for new ideas and good solutions.

2009 / 2010

In 2009 / 2010 Gillenkirch presents itself to the outside world as a whole for the first time. A corporate image is built up, a general catalogue is created, a new website and our first corporate film lands in the can. At the same time, the design department refines the details of the machines in terms of quality and hygiene and supplements the creation of drawings with the introduction of 3D visualisation.

2010

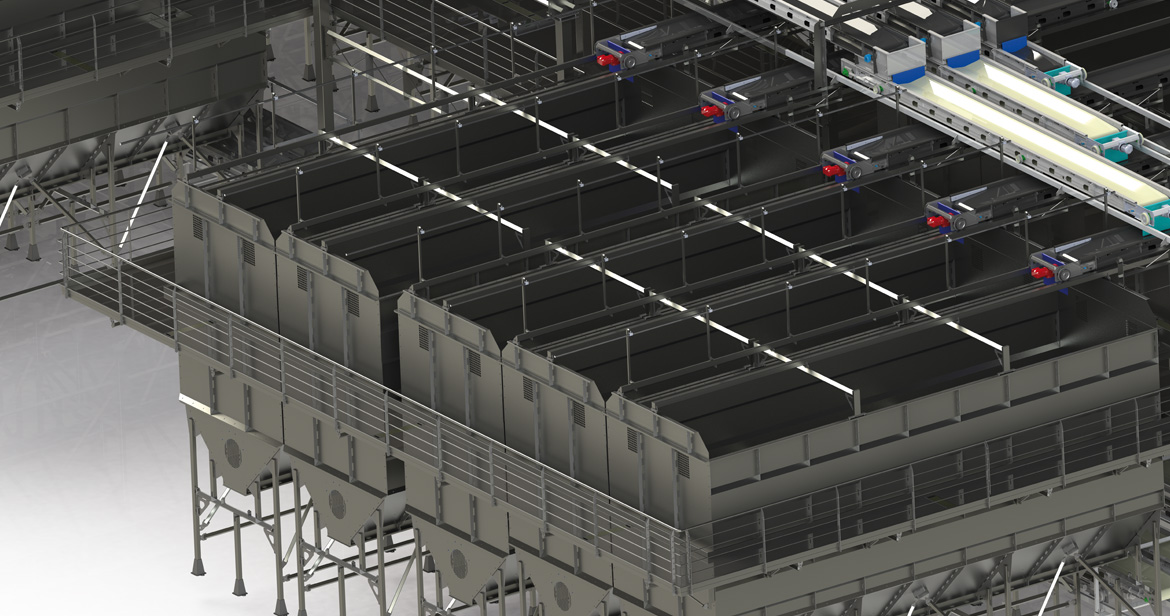

In 2010, the company receives the order from “AK-Agarkontor” for the construction of a high-quality washing and sorting plant for table potatoes. Both parts of the plant are first-classly processed down to the smallest detail and are connected with each other in a high-performance manner and represent a further milestone in quality and hygiene.

2012

The company expands its operations in Bremervörde. In May 2012, the company breaks ground for the construction of the new warehouse and loading hall and in September, the company has a total area of 3000 m² for the production of machines and conveyor belts. In order to meet the increasing demands for plant construction, the company founds Fresh Link & Packaging Solutions, based in the Czech Republic, together with Rostislav Bucek.

2012 / 2013

The company receives the largest order in its history: the construction of a washing and hopper plant for a leading French fries manufacturer in the USA. The plant will be manufactured in 2012 at the three locations Dinslaken, Bremervörde and Jihlava. In January 2013, the plant goes into operation in the USA with a total capacity of more than 30,000 truckloads of potatoes per year. The successful realisation sets new standards in conception, processing, quality, hygiene and performance requirements.

2014 / 2015

In 2014/2015, Gillenkirch is implementing a complete plant concept for the processing of table potatoes in Canada. This is the first time that such a complex plant concept is being realised in one assembly step, as in the past similar projects were developed over several years. At the same time, Michael Gillenkirch, the Managing Director of Engineering and Sales, succeeds his father and takes over responsibility for Gillenkirch Packaging Systems as Managing Director.

1948

1966

1969

1973

1976 / 1977

1980

1988

1993

1995 / 1996

1997

2000

2001 / 2003

2008

2009 / 2010

2010

2012

2012 / 2013

2014 / 2015

This might also interest you.

The company

Locations

Contact us:

Do you have any questions about our machines and plants, or do you need our advice? Simply contact us via our form. We will get back to you as soon as possible.